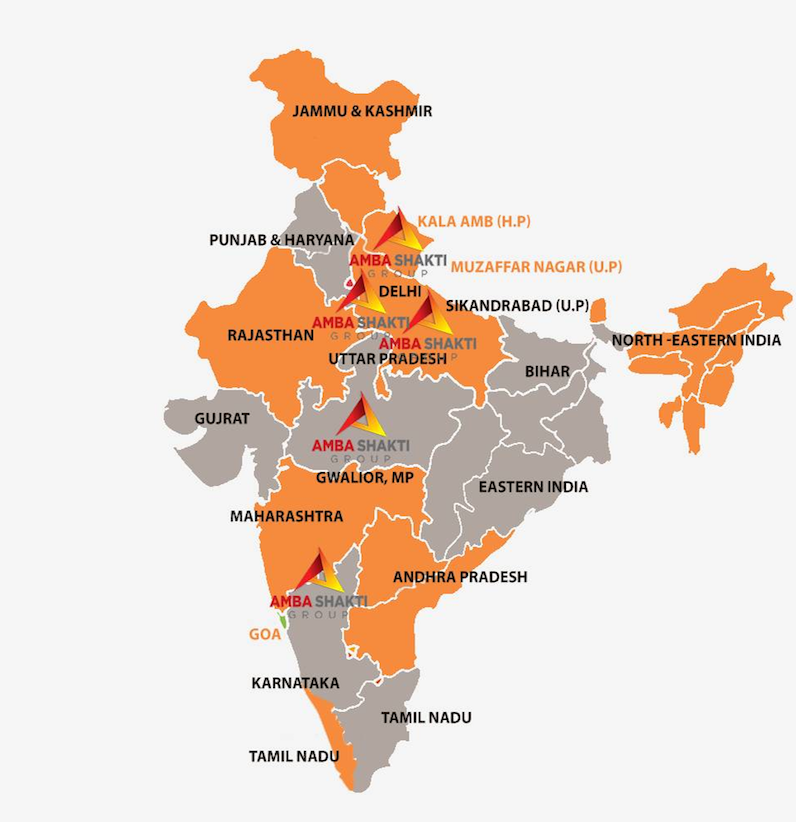

Founded by Mr. S.K. Goel in 1974, Amba Group today is recognized as one of the fastest growing companies in India. We have a Pan-India presence. The group is working in three diffrent sectors:

1. STEEL

2. LPG CYLINDERS

3. REAL ESTATE

Now, under the leadership of Mr.Pankaj Goel, Our primary goal is to see a confident smile of satisfaction on all our clients face by producing best quality products.

The group is constantly diversifying itself, touching all the major areas & fields and has set up 'Integrated Steel Plant', where we manufacture steel right from processing Iron Ore to Sponge Iron, Billets and finally finished steel products as well as generation of own power. Our Main Product is TMT Bar. We Produce TMT Bar Under Two Names "Amba Shakti Tricore" and "Amba Shakti SD TMT".

The first integrated plant of the group, Amba Shakti Steels Ltd. laid the strong foundations of AMBA Group, as a brand, synonymous with high quality TMT rebar.

The plant, which started with induction furnaces, reheating furnace and a semi-automatic rolling mill has continually upgraded itself in production capacity and to use the latest technologies like direct hot charging to produce high quality rebar catering to the vast demand in the northern region of the country.

At this plat we produce TMT bars under the brand name of Amba Shakti Tricore, which over time has developed its vast network of loyal, commited and well-established dealers & distributors.

Despite 28 glorious years of rigorous operations, the plant still outshines modern day integrated steel plant in efficiency and quality products.

The latest addition to the group, Amba Shakti Industries is the biggest jewel in the Crown of Amba Shakti. Boasting of a production capacity of 0.5 Million Tons of Rebar, it is the largest plant in the entire Northern India Region.

This is an integrated plant that means it has both, a steel melting shop (SMS) and a rolling mill. The hot billets produced from the SMS is directly fed into the rolling mill. This allows for stringent quality controls which are not possible for stand-alone rolling mills and provide savings in cost and energy.

The SMS consists of two 40 tons Induction furnaces and a high speed Continuous Casting machine allowing productions of as much as 90 tons per hour. The billet from the CCM is then directly fed into the state of the Art, 0.5 Million tons capacity Horizontal/Vertical Slitting Rolling Mill. This Rolling mill incorporating the best and latest technologies of the World, produces the highest quality Rebar.

Among the various other new technologies added to this plant is also a World Class Pollution Control System and zero usage of fossil fuels like Furnace oil, Coal, etc., which makes this plant the cleanest and most environmentally friendly. (This has been integrated into all the group plants as per our commitment towards providing a better world for our future generations).At this plant we produce TMT bars under the brand name Amba Shakti SD.

Catering the needs of western and southern regions, this is a similar plant to the one in Muzaffarnagar and has well been upgraded with the latest technologies to produce the best quality rebar.

A pioneer in the South, this was one of the first secondary steel plants to produce rebar in the southern region. It has since inspired many more plants to become operation in the area and cater to the vast growing demand.